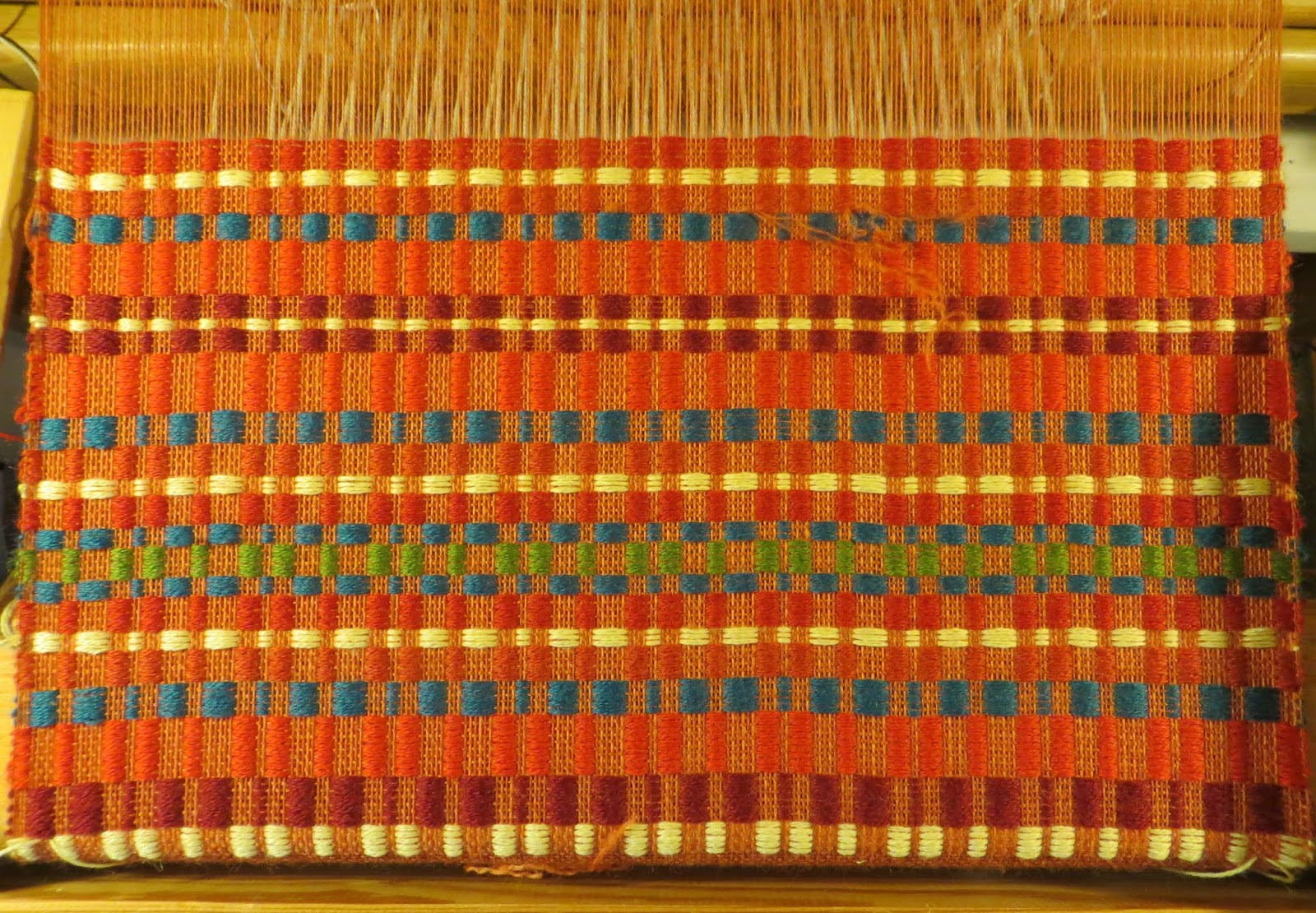

This picture of the yarns that I am using for the scarf gives a better idea of the colours - something along the lines of a old copper pot encrusted with verdigris!

Wednesday, May 13, 2015

Tuesday, May 12, 2015

Differential Shrinkage Scarf

I put on the warp for this scarf a couple of weeks ago but I have been hit by the lurgy (flu/cold) so until today I had done nothing. Today I wove for three hours and the scarf is about half done.

The design is taken directly from Evening Sunset Scarf by Stefanie Meisel in Handwoven Sept/Oct 2004. I have changed one of the yarns (18/2 Merino replaced with 20/2) which should make little difference. This scarf will differ from the last one I did in that there are ruffles on the outer edge of the scarf.

The photo below doesn't do justice to the colours. The merino is a vibrant turquoise green and the non-shrinking tencel is two shades of copper. I will pay more attention to my lighting when I next take a picture.

This is the first time that I have used a "crocodile clip" temple and it is working very nicely. I have used a couple of sawn down wood working clamps to to hold the cord between the clips and the weights. The trick is to make sure that the arrangement clears the beater and doesn't get in the way when throwing the shuttle

The design is taken directly from Evening Sunset Scarf by Stefanie Meisel in Handwoven Sept/Oct 2004. I have changed one of the yarns (18/2 Merino replaced with 20/2) which should make little difference. This scarf will differ from the last one I did in that there are ruffles on the outer edge of the scarf.

The photo below doesn't do justice to the colours. The merino is a vibrant turquoise green and the non-shrinking tencel is two shades of copper. I will pay more attention to my lighting when I next take a picture.

This is the first time that I have used a "crocodile clip" temple and it is working very nicely. I have used a couple of sawn down wood working clamps to to hold the cord between the clips and the weights. The trick is to make sure that the arrangement clears the beater and doesn't get in the way when throwing the shuttle

Tuesday, April 21, 2015

Ruffled Scarf in Collapse Weave

I started this scarf in the middle of last year. It has been languishing in a box un-twizzled and unwashed. That has been rectified and here it is.

The yarns are 18/2 Merino (the shrinker) and 8/2 Tencel (the non-shrinker). I have followed almost to the letter (apart from the colours) the instructions in the article by Stefanie Meisel in Handwoven 2004 Sept/Oct.

Here are some of the details;

The yarns are 18/2 Merino (the shrinker) and 8/2 Tencel (the non-shrinker). I have followed almost to the letter (apart from the colours) the instructions in the article by Stefanie Meisel in Handwoven 2004 Sept/Oct.

Here are some of the details;

Monday, April 13, 2015

Weavers Elbow

I think that I may have been a little too gung-ho in my experiments with end feed shuttles (see last post). For the past month I have been afflicted with very painful tennis elbow (or maybe golfers elbow) which has not been caused by tennis (wrong arm) and which has been quite incapacitating. The only thing that I can think of that could have caused it is weaving with a half kilo shuttle! Idiot!

Sunday, March 1, 2015

End Feed Shuttles

Weaving the Waffle Weave Shawl (it is off the loom and resting in preparation for being fringed and washed) necessitated fairly frequent colour changes so I took the opportunity to try some different shuttles.

For the beige areas of the shawl I used a Crossley hand weaving shuttle. I wish that I could get another. It fits nicely in the hand and just glides across the shed straight and true with the smallest of flicks. It has a Honex tension adjustment mechanism; I think that I was told that it is made of persimmon wood.

I have two AVL 11" shuttles that I used for the coloured stripes. I bought these some time ago and have used them extensively over the years as they seem to be just the right size for scarves. I find them a little on the light side after using the Crossley and they are not very kind to any errant warp ends. As the inset on the photo below shows the tips are square rather than tapered and the Honex mechanism protrudes above the body of the shuttle. When using them I cover this protrusion with masking tape but the blunt end can still cause problems if I slightly mis-throw the shuttle or have a lazy warp end. I shan't be using these again until I have had a go at them with an angle grinder, rasps and sandpaper.

Over the years I have built up a small collection of metal tipped end feed shuttles that are for use with a fly shuttle. Because they have sharp metal tips they are not, in theory, that much good for being hand thrown but I decided to try anyway with some of the blunter ones.

The first one tried quite successfully was another Crossley which I have shown below. The tension of the yarn as it leaves the shuttle is controlled by fur like fabric that brushes against the side of the filled pirn and by some felt in hole though which the yarn leaves the shuttle. I presume that each shuttle was designed for a specific small range of yarn thicknesses as there is no mechanism for adjusting the tension. It worked fine with the yarn that I was using (11.5/2 wool). I don't have any pirns that fit but one from my AVL shuttle worked nicely enough.

The second metal tipped shuttle that I tried was a bit of a beast but it was surprisingly easy to use. It has an adjustable Honex type tension adjuster. I thought that it might be a bit hard on the wrists but I wove with it for over an hour with no adverse effects.

I shall blunt the tips of these two shuttles a little and then they can move from my shuttle collection box to my working shuttle box.

For the beige areas of the shawl I used a Crossley hand weaving shuttle. I wish that I could get another. It fits nicely in the hand and just glides across the shed straight and true with the smallest of flicks. It has a Honex tension adjustment mechanism; I think that I was told that it is made of persimmon wood.

I have two AVL 11" shuttles that I used for the coloured stripes. I bought these some time ago and have used them extensively over the years as they seem to be just the right size for scarves. I find them a little on the light side after using the Crossley and they are not very kind to any errant warp ends. As the inset on the photo below shows the tips are square rather than tapered and the Honex mechanism protrudes above the body of the shuttle. When using them I cover this protrusion with masking tape but the blunt end can still cause problems if I slightly mis-throw the shuttle or have a lazy warp end. I shan't be using these again until I have had a go at them with an angle grinder, rasps and sandpaper.

Over the years I have built up a small collection of metal tipped end feed shuttles that are for use with a fly shuttle. Because they have sharp metal tips they are not, in theory, that much good for being hand thrown but I decided to try anyway with some of the blunter ones.

The first one tried quite successfully was another Crossley which I have shown below. The tension of the yarn as it leaves the shuttle is controlled by fur like fabric that brushes against the side of the filled pirn and by some felt in hole though which the yarn leaves the shuttle. I presume that each shuttle was designed for a specific small range of yarn thicknesses as there is no mechanism for adjusting the tension. It worked fine with the yarn that I was using (11.5/2 wool). I don't have any pirns that fit but one from my AVL shuttle worked nicely enough.

The second metal tipped shuttle that I tried was a bit of a beast but it was surprisingly easy to use. It has an adjustable Honex type tension adjuster. I thought that it might be a bit hard on the wrists but I wove with it for over an hour with no adverse effects.

I shall blunt the tips of these two shuttles a little and then they can move from my shuttle collection box to my working shuttle box.

Tuesday, February 17, 2015

Waffle Weave Shawl

.jpg) After a little break from weaving I have started work on a Waffle Weave Shawl. The warp is a straight 24 threading left over from the mock leno shawl that I wove just before Christmas.

After a little break from weaving I have started work on a Waffle Weave Shawl. The warp is a straight 24 threading left over from the mock leno shawl that I wove just before Christmas.I am weaving bands of colour which will use up some of my old stocks of Bendigo 2 ply. The draft uses a 4 shaft point threading which I have extended to 24 shafts. It is all coming along nicely and should be finished by the end of the week.

Thursday, January 1, 2015

Thursday, October 23, 2014

Huck Baby Blanket

I have just finished weaving a baby blanket in huck lace. My starting point was the article by Linda Ligon in the 1999 May June edition of Handwoven. As I was planning to put on a straight 24 threading I worked out a similar pattern (originally from Carol Strickler) in the lift-plan of my weaving software (Pixeloom). Shafts 1 and 12 provided the plain weave for the selvedges.

There were 666 ends in the draft so it seemed to take a long time to get the loom ready for weaving.

I got into a bit of a muddle on how to get the taped bouts from sectional warping into position for threading but with help from members of Weavetech I got there in the end.

The blanket is fairly straightforward and has been sent off to the baby. This exercise was interesting for me because it represented several firsts for me.

I think that I am going to have to find some instructions on fashion photography- I frequently feel that my pictures don't do justice to the work.

I think that I am going to have to find some instructions on fashion photography- I frequently feel that my pictures don't do justice to the work.

There were 666 ends in the draft so it seemed to take a long time to get the loom ready for weaving.

I got into a bit of a muddle on how to get the taped bouts from sectional warping into position for threading but with help from members of Weavetech I got there in the end.

The blanket is fairly straightforward and has been sent off to the baby. This exercise was interesting for me because it represented several firsts for me.

- Weaving in cotton. I have woven samplers in 4 ply cotton but this was the first time that I had used cotton (8/2) for a complete piece. I had to beat harder than I usually do to maintain 18ppi. I don't know if this was because of the yarn, the draft or the width.

- Weaving with width. The width of the warp on the loom was 37" which is over a foot wider than anything I have done before. I played around with various shuttles and practiced my throw; I got on best with a 38 cm shuttle with rollers. Once I got the rhythm going there were no problems

- Weaving standing up. I have raised my loom on bricks by 8" and I wove standing up. No shoulder pains and it was much easier to move around the loom to see what is going on and advance the warp. No more hopping on and off the bench and they do say that too much sitting is bad for you.

I think that I am going to have to find some instructions on fashion photography- I frequently feel that my pictures don't do justice to the work.

I think that I am going to have to find some instructions on fashion photography- I frequently feel that my pictures don't do justice to the work.

The picture below is from my weaving notes. The calculations on shrinkage and draw in were pretty accurate which gives me a good reference point for the future. There is enough warp left on the loom to enable me to tie on the next warp which will save time on the threading. The warp is set at 18 epi which is just right for twill in Bendigo 2 ply or plain weave/lace in cottolin. Mmm...

Weaving Notes

Labels:

8/2 cotton,

baby blanket,

Carol Strickler,

huck,

Linda Ligon,

PixeLoom,

weaving standing up

Monday, September 15, 2014

Sunday, August 24, 2014

Delayed project

After I finished my last differential shrinkage shawl I wound another warp onto the back beam and was ready to start the tie on in April. Other things intervened and I did not return to the project until earlier this month. The shawl is now off the loom and all that I have to do is full it and it will be done.

For this red shawl I have used the same yarns and draft as the blue/turquoise one. The birthday of the intended recipient is long gone and she is expecting in about 8 weeks which means that I need to get a move on with a baby blanket. I have toyed with doing an overshot coverlet but I haven't left myself enough time so I am planning something in huck in 8/2 cotton.

For this red shawl I have used the same yarns and draft as the blue/turquoise one. The birthday of the intended recipient is long gone and she is expecting in about 8 weeks which means that I need to get a move on with a baby blanket. I have toyed with doing an overshot coverlet but I haven't left myself enough time so I am planning something in huck in 8/2 cotton.

Monday, July 14, 2014

Saori Weaving at Sturt

I spent a very enjoyable week at the Sturt Winter School in a workshop run by Kaz Madigan on Saori Weaving. I have to confess that I had a bit of an internal struggle coming to terms with some of the concepts behind this style of weaving but I think that I got there in the end. Kaz describes it all here much better than I could.

Here are some pictures of my output; there are a lot of very interesting things to be done in a bit of plain weave and when I have finished all my other current projects I shall give some of them a try.

Some of the ones that I tried -

Here are some pictures of my output; there are a lot of very interesting things to be done in a bit of plain weave and when I have finished all my other current projects I shall give some of them a try.

Some of the ones that I tried -

- Push the weft to make space for weaving lozenges

- Wind a bobbin with two twisted yarns and then reverse the direction of the twist. When this energised yarn is used in the weft it gives an undulating twill effect

- Creating uneven tension on the warp

The specialised Saori looms are lovely to use and have several very interesting design features.

Monday, February 24, 2014

Wednesday, February 19, 2014

Quills and Twisters

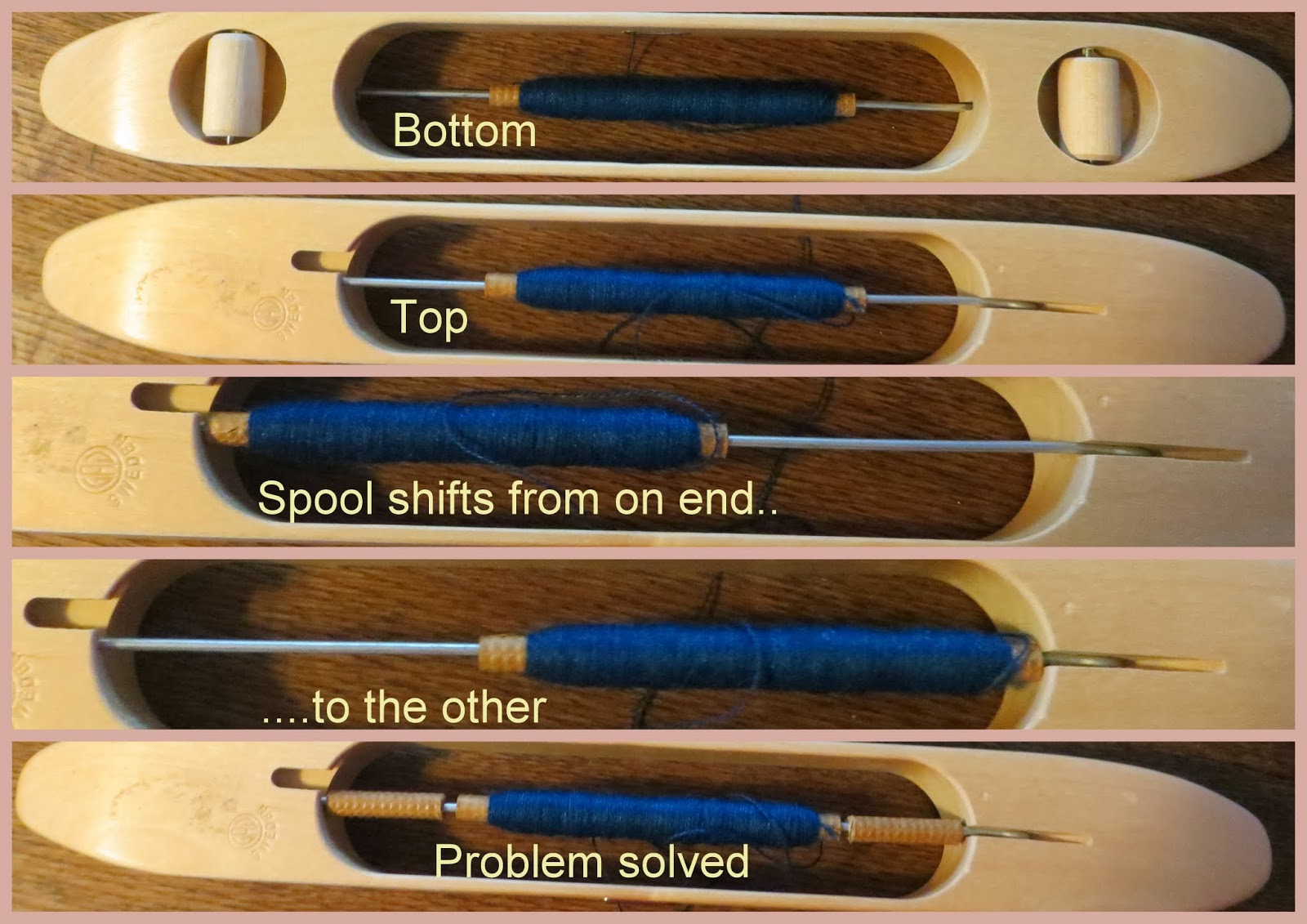

In a previous post I related how I was having problems with the spools in my new shuttle. I had some very pertinent and welcome comments from Maliz who gave me details and advice about the the benefits of winding a quill of the appropriate size. I have tried it and it works very nicely as the photos show.

I have finished the weaving the shawl and it is off the loom and it looks shocking which is what one would expect for something woven at half the plain weave epi/ppi.

I still have to full the scarf so I am afraid that I am going to miss my Friday birthday deadline. I hope that the recipient will understand!

I have finished the weaving the shawl and it is off the loom and it looks shocking which is what one would expect for something woven at half the plain weave epi/ppi.

I have started on the fringes which is fairly time consuming even with my twister. Thank goodness for audio books (Bleak House).

I still have to full the scarf so I am afraid that I am going to miss my Friday birthday deadline. I hope that the recipient will understand!

Sunday, February 16, 2014

Red dots on the beater bar

I have had a lovely day listening to music and weaving with the occasional foray into the garden between showers. If I focus tomorrow I may well get the weaving of this shawl finished.

I have put a couple of red dots on the beater bar. These are to guide my thumbs to the correct position so that I hold the beater in the middle. I noticed a tendency for slight slope in the last pick at the fell; one side was nearer to the previous pick than the other side. I put this down to either the fact that I wasn't aligning the temple parallel to the fell or that it was because of my habit of grasping the beater off centre - hence the red dots.

I am taking care with the temple and centering my hand on the beater and the problem has gone away. Successful problem resolution is always very satisfying.

I have put a couple of red dots on the beater bar. These are to guide my thumbs to the correct position so that I hold the beater in the middle. I noticed a tendency for slight slope in the last pick at the fell; one side was nearer to the previous pick than the other side. I put this down to either the fact that I wasn't aligning the temple parallel to the fell or that it was because of my habit of grasping the beater off centre - hence the red dots.

I am taking care with the temple and centering my hand on the beater and the problem has gone away. Successful problem resolution is always very satisfying.

Saturday, February 15, 2014

The picks are all right, but the selvedges; Oh my!

The warp is on for the DS Scarf #2 and I have started weaving the first sample which where I check that everything is in order, the tension is right, the warp advances smoothly, the threading and sleying is correct (alas, three cross overs) that the ppi is correct and the selvedges are behaving. After a while I got the beat where it should be (12ppi) but the selvedges were decidedly wonky.

I determined that the reason was that I was using a new shuttle. Normally when drawing a boat shuttle out of the shed I move it forward (to create the weft angle), stop the spool from letting out any more yarn by putting my thumb on it so that I am pulling the selvedge on the opposite side in just a little bit before I close the shed, release the tension on the weft and beat.

I have bought a new Glimakra shuttle, one with wheels. I wanted a shuttle that was light and well spread out so that it didn't go crashing through the floor of the shed. At only 6 ends per inch of 20/2 yarn the shed floor is not that robust. The shuttle trundles through the shed very nicely but because it is quite long the spool can shift from end to end which meant that I was missing the spool with my thumb and therefore not applying any tension to the selvedge. I have resolved the problem by cutting bits of another spool and using them as wide washers. Picture #4 above shows a marked improvement on the last dozen picks (though the beat looks to be a bit variable!

I shall weave another 9" of sample before I start to weave the scarf proper - that should be enough to get everything bedded in.

PS. It has just occurred to me that what I am calling spools should in fact be called quills - I shall have to check.

I determined that the reason was that I was using a new shuttle. Normally when drawing a boat shuttle out of the shed I move it forward (to create the weft angle), stop the spool from letting out any more yarn by putting my thumb on it so that I am pulling the selvedge on the opposite side in just a little bit before I close the shed, release the tension on the weft and beat.

I have bought a new Glimakra shuttle, one with wheels. I wanted a shuttle that was light and well spread out so that it didn't go crashing through the floor of the shed. At only 6 ends per inch of 20/2 yarn the shed floor is not that robust. The shuttle trundles through the shed very nicely but because it is quite long the spool can shift from end to end which meant that I was missing the spool with my thumb and therefore not applying any tension to the selvedge. I have resolved the problem by cutting bits of another spool and using them as wide washers. Picture #4 above shows a marked improvement on the last dozen picks (though the beat looks to be a bit variable!

I shall weave another 9" of sample before I start to weave the scarf proper - that should be enough to get everything bedded in.

PS. It has just occurred to me that what I am calling spools should in fact be called quills - I shall have to check.

Friday, February 14, 2014

Warping Mill

When I was on my recent workshop in Mittagong I used a warping mill for the first time. I liked it so I have just bought one. I find it very easy to use and I think that for shorter warps it is easier than using a warping wheel and sectional warping.

Normally when I am winding a warp with different yarns I wind the warp chains following the warp order as it is in the threading. So for this deferential shrinkage scarf (see previous post) previously I would have wound 30 ends of yarn A followed by 30 ends of yarn B, followed by 30 ends of yarn A and so on.

In this instance I wound all of yarn A on one chain and all of B on another. All went well and it was a speedy process. The pictures below show Yarn A spread in the raddle leaving spaces for yarn B.

I shan't be doing it again! The time saved in winding the warp was lost because I had to mess about with two rods attached to the back apron rod and two sets of lease sticks. Still, you have to try these things otherwise you could miss out on some cunning improvements!

Normally when I am winding a warp with different yarns I wind the warp chains following the warp order as it is in the threading. So for this deferential shrinkage scarf (see previous post) previously I would have wound 30 ends of yarn A followed by 30 ends of yarn B, followed by 30 ends of yarn A and so on.

In this instance I wound all of yarn A on one chain and all of B on another. All went well and it was a speedy process. The pictures below show Yarn A spread in the raddle leaving spaces for yarn B.

I shan't be doing it again! The time saved in winding the warp was lost because I had to mess about with two rods attached to the back apron rod and two sets of lease sticks. Still, you have to try these things otherwise you could miss out on some cunning improvements!

Wednesday, February 5, 2014

Yarn shopping

I have been yarn shopping.

The cones are of 20/2 NM Merino which hasn't been treated so it shrinks and felts very nicely as shown here and here. I bought it from Yarn Barn, West Coburg, Victoria.

I bought the skeins from Glenora Weaving and Wool which is based in Gerringong, New South Wales. I took a train down from Sydney so that I could have a browse before buying. I bought some more Mora 20/2, Alpaca Silk 28/2 and variegated 20/2 Silk. All are destined to be combined with the 20/2 Merino in various ways.

The first project will be a differential shrinkage shawl, similar to the scarf that I wove just before Christmas. I will be using analogous shades of blue. The blue 20/2 merino (almost a Royal Blue) is to be partnered with some 28/2 Alpaca Silk (Peacock). The colours are not quite as close together as the photo below would suggest. The peacock yarn is, well, peacock!

I have completed my project plan and shall start putting on the warp tomorrow. My deadline for this shawl is the 21st February - delivered!

The Monks Belt that I was working on is trimmed and washed. Here it is in a couple of cushion mock ups.

The cones are of 20/2 NM Merino which hasn't been treated so it shrinks and felts very nicely as shown here and here. I bought it from Yarn Barn, West Coburg, Victoria.

I bought the skeins from Glenora Weaving and Wool which is based in Gerringong, New South Wales. I took a train down from Sydney so that I could have a browse before buying. I bought some more Mora 20/2, Alpaca Silk 28/2 and variegated 20/2 Silk. All are destined to be combined with the 20/2 Merino in various ways.

The first project will be a differential shrinkage shawl, similar to the scarf that I wove just before Christmas. I will be using analogous shades of blue. The blue 20/2 merino (almost a Royal Blue) is to be partnered with some 28/2 Alpaca Silk (Peacock). The colours are not quite as close together as the photo below would suggest. The peacock yarn is, well, peacock!

I have completed my project plan and shall start putting on the warp tomorrow. My deadline for this shawl is the 21st February - delivered!

The Monks Belt that I was working on is trimmed and washed. Here it is in a couple of cushion mock ups.

Wednesday, January 29, 2014

Monk's Belt progress

I couldn't weave for a couple of days because of a ricked back. I am now back on track and should be finished tomorrow. It has been quite slow going with the frequent pattern weft changes and I am going to have do a little bit of work with a tapestry needle on the selvedges when the piece comes of he loom. I must finish it soon as I need the loom for some scarves that I am planning; more differential shrinkage

My wife has decided that it is worthy of becoming the front of a cushion cover - praise indeed!

Wednesday, January 22, 2014

Monk's Belt

I wove a Monk's Belt sampler in 2007 and it has been pinned to the back of a cupboard door ever since I wove it. I have admired it from time to time and vaguely thought about doing some more but nothing has ever eventuated.

In September last year a wove some Brighton Honeycomb scarves. The scarves were finished some time ago but I have yet to fringe, finish and photograph them in all their glory. They took second place to all the excitememnt of playing with my counterbalance loom and differential shrinkage. There was about two yards of warp left on the loom when I had finished weaving.

I have ordered some more 20/2 merino in several colours for my next foray into differential shrinkage and double weave. I have to get a birthday scarf finished and delivered by mid February so I hope that the yarn arrives soon.

In the meantime I am weaving some Monk's Belt on the warp left over from the Brighton Honeycomb. The weft is Bendigo 2 ply which I have re-sleyed to 15epi ( a tightish plain weave) and I am using the same yarn for tabby and doubled for the pattern weft. I am not sure to what the use the final product will be put; perhaps a table runner or a wall hanging for a gloomy corner.

I have had to rummage through my unused equipment box to find enough shuttles. The bottom shuttle in the picture below is my shuttle of choice, an AVL end feed but I have never used the top three before.

The pattern weft colours are those that I used for a multi-coloured warp early last year. I think that I have enough warp for three 24" hangings. This first one is fairly conventional; I might break out a bit for the next two.

Thursday, January 16, 2014

Double Weave with Differential Shrinkage

At the Contemporary Doubleweave Workshop I decide that I wanted to try some form of combination of double weave and differential shrinkage. Our tutor Liz sketched out a design for me (see the squared paper below) and I worked it into a draft and plan for a sample.

I started weaving it at the workshop but with the distractions of the interesting things that everyone else was doing I didn't get it finished until I got home

This is what the sample looked like when I took it of the loom

and this is what it looked like when I had finished it.

This piece will probably end up as a gift for a small niece. I need to think about the colours but I have enough now to enable me to work on a full size version with four panels. I am delighted with the results and I don't think that I would have got anywhere near weaving something like this if it hadn't been for the workshop.

Tuesday, January 14, 2014

Contemporary Doubleweave Workshop

Well that workshop was fun and very informative. I have learnt a lot from both our tutor and from my fellow students. Now it is just a case of putting it into practise. I will not be giving any hostages to fortune by listing what I have learnt; I shall talk about each topic when I have actually done it.

The pictures show some of the work that was done ( I shall be plagarising) and the spacious weaving rooms where we produced it. I wonder what the topic will be for next year's workshop.

The pictures show some of the work that was done ( I shall be plagarising) and the spacious weaving rooms where we produced it. I wonder what the topic will be for next year's workshop.

Monday, January 6, 2014

Weaving Workshop - Contemporary Double Weave

It is just before 7:00 am on Monday morning and I am in Mittagong. I am just about to start week long workshop, "Contemporary Double Weave: reuse, layers and containers with Liz Williamson" which is being held at the Sturt Craft Centre and I have to confess to being a little bit excited.

My wife drove me down here last night (about 100k from Sydney) and I am staying in a student hall - very novel! The grounds of the Sturt Craft Centre are lovely, the buildings are set in very satisfying gardens with lots of arbors, pergolas and woodland walks.

My wife drove me down here last night (about 100k from Sydney) and I am staying in a student hall - very novel! The grounds of the Sturt Craft Centre are lovely, the buildings are set in very satisfying gardens with lots of arbors, pergolas and woodland walks.

Wednesday, January 1, 2014

Weaving Focus

One of the problems I have when I am weaving is that my mind tends to wander off so that I loose the focus on what I am trying to do. A similar thing happens to me when I am listening to music or trying to meditate.

I end up thinking about what we should be having for supper or how I am going to solve the problems of the world and before I know it a selvedge has pulled in, the beat has gone to the dogs and something horrible has happened to a thread at the back of the loom.

On my last project (Differential Shrinkage Scarf) where concentration on the technique was so important ( beating 10 ppi with a 20/2 weft needs nerves of steel) I wrote myself a little list and pinned it to the loom and read it out loud to myself as I wove. I consider myself to be an occasional weaver so I probably don't have the fully developed muscle memory that is needed to get all the little complex movements just right. It is early days yet but I think that this little weaving chant and check list might help.

I would be interested to hear if other people have a "focus" problem and how they resolve it.

I end up thinking about what we should be having for supper or how I am going to solve the problems of the world and before I know it a selvedge has pulled in, the beat has gone to the dogs and something horrible has happened to a thread at the back of the loom.

On my last project (Differential Shrinkage Scarf) where concentration on the technique was so important ( beating 10 ppi with a 20/2 weft needs nerves of steel) I wrote myself a little list and pinned it to the loom and read it out loud to myself as I wove. I consider myself to be an occasional weaver so I probably don't have the fully developed muscle memory that is needed to get all the little complex movements just right. It is early days yet but I think that this little weaving chant and check list might help.

I would be interested to hear if other people have a "focus" problem and how they resolve it.

Subscribe to:

Posts (Atom)