Gangewifre Weaving

A weaving blog of the what, why and how of the work I have been doing

Thursday, March 11, 2021

Pipe Loom

Friday, February 19, 2021

Abstract Tree

|   |

Saturday, August 1, 2020

Monday, May 11, 2020

Soumak Doodles

These pictures various stages of a little bit of fun that I been having with soumak. I referred to various You Tube videos and the magnificent "P. Collingwood- The Techniques of Rug Weaving". There was a bit of warp pulling with the curved piece.

Monday, April 20, 2020

Tapestry with supplementary warps

Supplementary Warp Tapestry

I wove this between October 2019 and March of the following year. It started as a straight forward sampler loosely following the first one in Nancy Harvey's book "Tapestry Weaving - A Comprehensive guide. As I went I put in some supplementary warps and wove them in various fashions to have areas of doubleweave.

The supplementary warps were woven on the surface of the ground cloth and tucked behind when no longer needed. In the picture above the bottom three have been woven as loops, two at an angle and the middle one straight. The top row has two stuffed pockets and one wavy long loop.

The picture above shows the start of the supplementary warps. I started weaving normally. I looped the supplementary warps around the existing warps. They are visible below the white header. When not being used the sup. warps stay at the back (nicely bundled to to keep them under control. When needed they are pulled through to the front. In this picture they are all at the front; only the middle group is tensioned.

Tension is applied by running the supplementary warps up and over the raddle. In this picture on the left is a sup. warp set under tension at an angle. The weaving of the middle set is finished and they have been passed to the back. The set on the right has been pulled through to the front and are just hanging around waiting for something to happen to them.

#4. This picture shows the sup. warp passing over the raddle.

#5 And here they are hanging down the back and tensioned with fishing weights. When a set of warps are finished on the front the weights are removed and they are passed back through the main warps to the back of the loom. After weaving a few more picks of the main layer snug up the bit of supplementary weaving and secure at the back with with knots. When the work came off the loom I secured the long warp floats at the back with some tacking stitches.

A crochet hook was invaluable and ready access to the back of the loom was essential.

Tuesday, January 29, 2019

Dish Cloths

I used a straight threading on 12 shafts and the weave structures are a mixture of basket weaves and huck. Started the project in April last year but it wasn't until January this year that I finished them off. Two of them are now in regular use.

T

T

Thursday, November 15, 2018

Selling my Glimakra/Toika Loom

Overview

- Frame, beater assembly, front and back warp, cloth and knee beams. GLIMAKRA STANDARD (120cm weaving width)

- Shedding mechanism and harnesses; TOIKA EW24 CONTROL UNIT (Dobby) with 24 SHAFTS

Background

Toika EW24 Control Unit

- Power

- Computer

- Pedal

Double Warp Beam

Glimakra Standard

- 10 shafts

- 120cm weaving width

- Dimensions 1.75m H x 1.60m D x 1.50m W

- 48 warp sticks

- 2 lease sticks

- 10 lamms

- 10 treadles

- 1 fabric protection board

- 4 rubber feet

- 2 tie bars

- 2 shaft holders

Accessories and Extras

The photos below show the accessories that are included with the loom.- 60 Warping sticks (46")

- 4 Lease sticks (46")

- 1 Raddle (takes 39" warp)

- 8 Reeds (see picture below for condition)

48" 12 D

48" 15 D

47" 18 D

40" 12D

40" 16 D

32" 10 D

30" 15 D

The manuals are shown below;

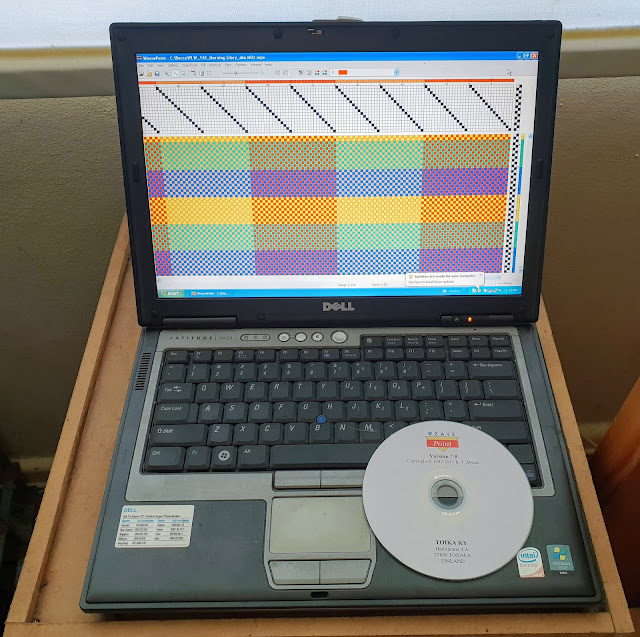

Also included is an elderly Dell Laptop (Windows XP) loaded with Weavepoint software and with the software disc.

Summary

To summarise, what is on offer is;- 120cm weaving width 24 shaft loom (Glimakra Standard) with automated control unit (Toika EW24)

- Double warp beams

- Accessories and reeds

- Manuals

- Computer and Weaving Software

What next

Wednesday, September 26, 2018

Sprang

I have been looking at my looms for over a year now; I think that the time has come to give it away.

Now this Sprang looks quite interesting with a nice small footprint.

Monday, June 5, 2017

Rotary Temple fitted to AVL Workshop Dobby Loom

I have an AVL WDL which I haven't used for about 6 years - I recently took it out of its packaging, gave it a good clean and got it ready to weave again. So that I could move it about I built a wooden dolly which the loom sits on very nicely.

Once the loom was on the dolly it occurred to me that the dolly might make a firm base for a framework to hold the rotary temple. I adopted a "suck it and see" approach to the design, clamping various bits of wood into place until I something that would hold the mounting brackets in the correct position. I screwed and glued it all together, put on the brackets and track and it works. I am still using clips to secure the framework in place until I think of something slightly more elegant.

|

| Initial mockup with uprights clamped to the loom frame and sitting on the dolly |

|

| A slightly diferent set up |

|

| Bracket clamped in place |

|

| The arrangement had to be different on each side to allow for the ratchet handle |

|

| Final design - uprights on the left |

|

| Uprights on the right |

|

| Upright, bracket, track and temple |

|

| In use |